Style: Horizontal

Description:

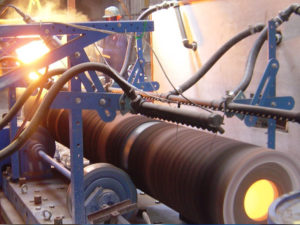

The Model K Horizontal Centrifugal Casting Machine is primarily designed to accommodate metal permanent molds, although they may be used with flasks and sand lined molds. These machines are especially suited for the production of long tubular castings. They lend themselves to jobbing foundry work as well as production work. Since the molds are efficiently cooled in the machine they may be kept in the machine and castings poured repeatedly until the order is filled.

CASTING DIMENSIONS

Model K machines can be supplied with one position or multiple positions in order to provide the required range of casting diameters and lengths. When changing positions it is necessary to adjust the runner pot elevation and spray car lance.

ELECTRIC DRIVE

Model K machines are driven by an electronically controlled variable speed drive that provides complete speed control over the maximum range required for the centrifugal casting work. It also allows for very low rotating speeds for cleaning the mold and preheating the mold. It is only necessary to preset the desired speed and then push the start button. The mold will accelerate up to the preset speed and maintains this speed within +/- 2%.

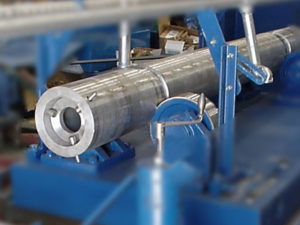

MOLD SPRAY

Automatic spray equipment is supplied as a standard part of a machine system. The spray lance is vertically adjustable so that the lance may be positioned accurately onto the centerline of the mold. Valves and regulators are used to control the amount of wash being sprayed on the inside of the mold. A continuously variable speed electric motor is used to provide the forward and reverse drive of the spray car. The spray car rides on tracks of a suitable length for the particular centrifugal casting machine.

MOLD COOLING

Model K machines include a type of water-cooling which impinges high velocity jets of water on the mold. The high velocity of this water wipes away steam that may be formed on the hot mold and increases the rate of heat transfer, thus providing a highly efficient transfer of heat from the mold to the water.

MOLD HEATING

Gas mold heaters are supplied for preheating the mold preliminary to spraying and/or casting. Natural gas, manufactured gas, butane, propane, etc. may be used with these burners. The heating system supplied on CCMCO horizontal trunnion type machines should not be the only source of mold heating in the customer facility. Supplied mold heating is for maintaining heat.

PRODUCTION RATE

The production rate of the model K machines is usually determined by the length of time required for the solidification of the metal. Complete cycle time for these machines varies from 15 minutes to an hour for large heavy-walled castings.

TYPES OF PRODUCTS

Castings produced on the model K machine may be processed into products such as corrosion or heat resistant pipe or tubes for chemical plant and heat treating furnaces. Other products are pump liners, ship-shaft liners, bearings, bushings, hollow billets, hollow rolls, etc.

Models and Specifications:

| Model NO. | WT. LIMIT(LBS) | Casting Size OD MIN. | Casting Size OD MAX. | Casting Length MIN | Casting Length MAX |

|---|---|---|---|---|---|

| K | 10000 | 4 | 30 | 36 | 160 |